TC2 Collet Connection System

About Trendsetter’s Collet Connection System (TC2)

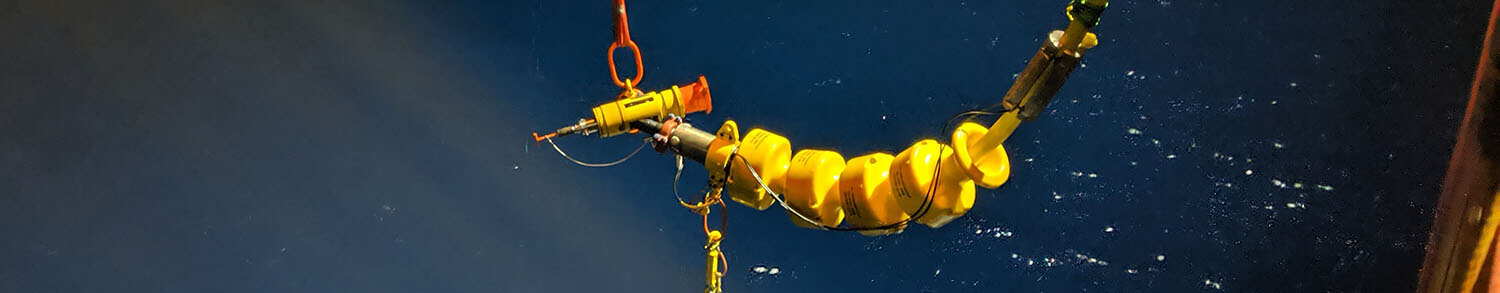

The TC2 Connector is a collet latched, subsea installable and recoverable vertical and horizontal connector that was developed with direct industry feedback regarding the complications and lessons learned associated with legacy 2” style connectors. The connector is capable of being terminated to a flexible flying lead via an industry standard API flange, 4-bolt hub style connection or equivalent. The TC2 Connector is also equipped with a 5-tonne rated lifting padeye for installation assistance. Customers want to ensure that a dependable seal is made and for that the TC2 Connector is equipped with a back-seal (external seal) test circuit that uses a standard API 17H ROV hot stab to operate. This feature allows the operator to verify the pressure integrity of Trendsetter’s proprietary TEX-2 gasket immediately after subsea installation of the flexible flying lead by using a small volume of test fluid provided by the ROV. The TC2 offers simple, efficient design based on three main principles: robustness, reliability, simplicity. These principles make the TC2 the ideal connector for subsea deployment and operations. Good things come in small packages.

|

Features and Benefits of the Trendsetter TC2 Collet Connection System:

Download Data Sheet (PDF)Download Hydraulic Data Sheet (PDF) |

Specifications

| Design Code | API 17D/6A |

| Design Life | 30 Years |

| Nominal ID | 2.0 in |

| Gasket | TEX-2 |

| Product Specification Level | PSL 3 or 3G |

| Material Class | EE/FF/HH |

| Rated Working Pressure | 15,000 psi |

| Temperature Rating | -20 to 250F |

| Maximum Water Depth | 10,000 ft |